Products

-

Fischerscope X-ray XDV-UE Semi

Automated measurement of wafer microstructures

-

Fischerscope X-ray 5000

Automated inline measurement of thin layers on products with large surfaces

-

Fischerscope XAN Liquid Analyser

Robust and efficient inline instrument for fully automated analysis of the metal concentration of up to 4 electroplating baths with X-ray fluorescence radiation

-

XRF for Inline Measurement Automated XRF System X-ray 4000

Inline measurement in strip electroplating

-

Fischerscope MMS Automation

All-purpose measuring system for automated coating thickness measurement and material testing

Automation is the next step in the development of the manufacturing industry. Fischer is a global turnkey solution provider which provides comprehensive automation systems with fast return on investment. All of our instruments are designed for fast and accurate measurement directly in the production process. We develop reliable solutions that are not only economical and precise, but also make your work as easy as possible. Our experts will work closely with you throughout the entire process in order to find the best measurement solution for your task. This includes conception to implementation and maintenance.

-

Automated Measurement Solutions | Inspection+Analyzing samples in running productions | Fischer

As experienced producers of measurement technology, Fischer has spent decades developing contact measuring systems with which, for example, the thickness of coatings can be determined directly in a running manufacturing line. Various interfaces ensure seamless communication of the measurement values and integrated I/O boards control interactions with other automation components. These systems, in combination with Fischers vast array of probes, ensure that a fitting solution can be found for virtually any measurement task. More efficient testing in automotive engineering: Fischer offers measurement solutions that guarantee that the tests conducted on auto bodies are not only fast but also performed under identical conditions. A measurement head guided by a robot will always take the measurements in exactly the same way, which – compared with manual coating thickness testing – greatly minimizes the scatter. A further advantage is the direct connection between the measuring and production systems. In terms of quality management, it means that, for each piece of car body panels built, there is a detailed account of the quality values relating to the coating process.

Fischerscope X-ray XDV-MUE Semi

Designed for quality control in the semiconductor industry, the FISCHERSCOPE® X-RAY XDV®-μ SEMI accurately measures microstructures on wafers – fully automatically. The whole automation unit is enclosed and therefore perfectly suited for use in clean rooms. FOUP and SMIF pods can be automatically docked to the measuring system. The handling and measurement inside the XDV-μ SEMI takes place entirely without manual intervention. Thanks to pattern recognition, the XRF gauge locates the specified measuring positions precisely and reliably. This automatic measuring process rules out damage and contamination caused by manual handling and ensures high throughput rates for inspecting valuable wafers.

Features

- Fully automated wafer handling and testing boost efficiency

- XRF system with excellent detector sensitivity and high resolution

- XRF system with polycapillary optics from the worldwide technology leader for measuring micro-spots

- Accurately tests structures up to 10 µm in diameter

- Automatic pattern recognition pinpoints the positions to be measured

- Multiple operating modes; manual measurement possible whenever required

- Flexible: docking station for FOUP, SMIF and cassette, for 6″, 8″ and 12″ wafers

Applications

Coating Thickness Measurement

- Base metallization layers (UBM) at the nanometer scale

- Thin lead-free solder caps on copper pillars

- Extremely small contact surfaces and other complex 2.5D / 3D packaging applications

Material Analysis

- C4 and smaller solder bumps

- Lead-free solder caps on copper pillars

Fischerscope X-ray 5000

The FISCHERSCOPE® X-RAY 5000 system continuously measures the layer thickness of thin layers on large-area substrates, for example in photovoltaics. The devices in this series form modular units that are easy to install in production lines. The X-RAY 5000 can be operated either in normal atmosphere or under vacuum. Furthermore, the XRF device is designed to be easy to maintain: the measuring head can be serviced without having to release the vacuum.

If the product moves or bulges during fabrication, it can skew the measuring results. For this reason, Fischer’s WinFTM software also has a built-in function for distance compensation, which can compensate for fluctuations of up to 1 cm without requiring additional distance sensors.

Features

- Continuous measurement in running processes with connection to production control systems

- Flexible use: for measurements in vacuum or in air; for sample temperatures up to 400°C

- Optionally available with water cooling

- Particularly robust design and construction for sustainably precise measurements under harsh conditions

- Outstandingly well-suited to coating thickness measurement and material analysis on products with large surfaces

- X-ray source, detector and primary filter can all be selected by the customer

Applications

- Thickness of CIGS, CIS, CdTe and CdS layers in the solar industry

- Thin layers just a few µm thick on metal strips, metallic foils and plastic foils

- Composition of CIGS, CIS, CdTe and CdS layers in photovoltaics

- Coating thickness control in continuous production

- Process monitoring in sputter and electroplating plants

- Systems comply with DIN ISO 3497 and ASTM B 568

Book a demo

Fischerscope XAN Liquid Analyser

Electroplating baths are subject to process fluctuations which can have a considerable influence on the deposition behavior and the resulting coating thickness. Continuous monitoring of the solutions is therefore essential.

The FISCHERSCOPE® XAN® LIQUID ANALYZER is a fully automatic X-ray fluorescence measuring device that allows you to keep an eye on the metal content of electrolyte solutions or electroplating baths 24/7. You can dispense with time-consuming and costly wet chemical analyses of your baths. Our patented flow cell with an availability of around one year is extremely low-maintenance. Fully automatic rinsing and monitoring processes work preventively, avoid contamination and thus ensure maximum technical availability of your measuring device.

The device can be used with maximum flexibility as a simple inline measuring device for the industrial production environment up to a complex multi-channel inline measuring system with full integration into a local manufacturing execution system (MES). The provision and documentation of the measurement data is fast, easy and in real time via fieldbus interface as well as csv file, so that your MES can use it for process control. The data can be visualized centrally on the device and at the control station or decentrally at the workstations. The measuring device is controlled via an integrated Siemens PLC with 24″ touch screen integrated in a standard control cabinet.

Advantages

- Market-leading precision: Combination of measuring cell and software ensures best measurement performance and safety

- Absolutely unique: No need to change the measuring cell

- Maximum service life: High availability of ≥ 1 year* due to innovative design and material selection

- Intelligent self-monitoring: Fully automatic, preventive rinsing and monitoring processes prevent contamination and ensure maximum technical availability

- No time-consuming spot checks and information gaps: Stay continuously in the picture about your electroplating process

- Extremely low maintenance: Robust construction and service-friendly design

- Safety in real time: Live measurement results as well as simple and fast documentation

*Dependent, among other things, on rinsing and cleaning cycles as well as composition of coating baths

Features

- Fully automatic sequential measurement of up to 4 plating bath solutions

- 1-channel to 4-channel solution

- Measuring method: Energy dispersive X-ray fluorescence measuring instrument (EDXRF)

- Microfocus tube with tungsten anode

- Silicon drift detector 50 mm² for highest precision

- Digital Pulse Processor DPP+ for minimizing measuring time and optimizing repeatability

- Fieldbus interface enables connection to higher-level control systems as well as equipment to equipment communication

Application

- Meeting all challenges: Measurement of a wide range of metallic bath solutions, such as zinc, nickel, zinc/nickel, gold, chromium and palladium

- Other metallic bath solutions on request

Book Demo

How does the solution analysis work?

The FISCHERSCOPE® XAN® LIQUID ANALYZER is directly connected to the plating bath via a tube. There, the solution is taken from the bath by a pump and directed to the flow cell inside the measuring device.

In the measuring cell, the solution analysis takes place by X-ray measurement. In this process, high-energy X-rays – the primary radiation – are sent from the X-ray tube to the sample. These X-rays strike atoms in the solution and ionize them. This means that an electron close to the nucleus is removed from the atom. Since this state is unstable, an electron from a higher shell fills the gap, emitting fluorescence radiation. The energy level of this radiation is like a fingerprint – characteristic of the element in question.

A detector captures the fluorescence and digitizes the signal. After the signal has been processed, a spectrum is created: the energy of the detected photons is plotted on the x-axis, and their frequency, the so-called count rate, is plotted on the y-axis. From the position of the peaks in the spectrum, the elements present in the solution can be identified. The height of these peaks provides information about their concentration.

After successful measurement, the solution is collected in a wastewater treatment tank or returned to the sampling point.

XRF for Inline Measurement | Automated XRF System | X-ray 4000

The FISCHERSCOPE® X-RAY 4000 is designed for measuring coating thicknesses during the strip electroplating process, for checking stamped parts and hot air solder-leveled strips or metal coatings on foils, for example. During the measurement, the galvanized strip is scanned using X-ray fluorescence analysis. The measurement results are both accurate and reliable. Fast mechanics for moving the measuring head around make it possible to take measurements at various places on the test piece. Due to the modular system architecture, the XRF measuring instrument can be adjusted according to your individual needs. If required, a second measuring head can even be installed for measuring the front and back of a product.

Inline measurements taken in real time and directly in the production line yield more readings – and more quickly – than your quality lab can provide. This makes it possible to identify trends in the coating thickness and quickly take corrective measures. As a result, the interventions required in the coating line are less severe. The advantage: You can control the process more accurately without having to set a safety margin on the coating thickness, which saves money.

Features

- Fast and reliable measurement using XRF

- All hardware and software components have been developed for inline measurement purposes

- Easy handling and automatic calibration ensure minimal set-up times

- Can be used flexibly by adapting to different layer systems and bandwidths (from just a few millimeters to one meter)

- Systems comply with DIN ISO 3497 and ASTM B 568

Applications

- Galvanic coatings such as Au, Ag, Pd, Ni, Cu etc. on stamped and solid strips

- Electrical contacts on strip material

- Hot air solder-leveled steel and non-ferrous metal coiled wires

- Functional coatings in the photovoltaics industry

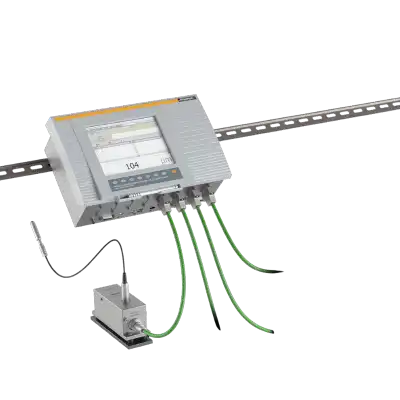

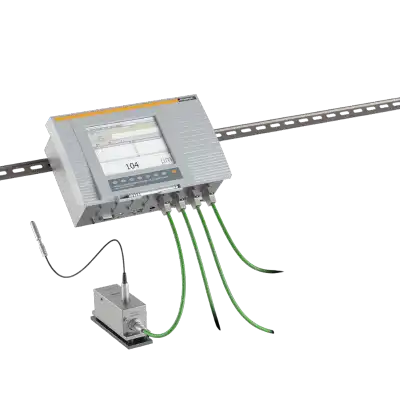

Fischerscope MMS Automation

The modular measurement system FISCHERSCOPE® MMS® Automation is the ideal solution for inline coating thickness measurement and material testing. Its standardized interfaces enable rapid integration in quality management systems and automated manufacturing processes. Whether you’re testing with just one probe on the head of an industrial robot or you’re working with up to four probes in parallel in a measuring station directly in your production line: The MMS Automation puts all of Fischer’s electromagnetic measurement methods at your fingertips.

Features

- Modular measuring system for coating thickness and conductivity

- Remote control via PLC

- Mount measuring modules and probes directly on the robot system or on in inline measuring station

- Module connects with base unit via cable suitable for drag chains up to 30m long

- Communication with higher-level control via Profinet or classic RS-232 interface

- For use in any industrial environment

Applications

- Electrically insulating layers on various metals, e.g. paint on steel or aluminum

- Non-magnetizable layers on ferrous metals, e.g. zinc, copper or chrome on steel

- Electroplated nickel layers on non-ferrous metals and insulating base materials

- Thickness of individual copper layers on multilayer circuit boards

- Testing of galvanic coatings

- Identification of non-ferrous metals by their electrical conductivity

Contact us now for more information

Whether you know what type of machine you require or have questions surrounding our product range, we are always happy to assist.

Get in touch and we will help you find the automation that best suits your needs. Our team has many years of experience and is always happy to answer your questions.

If you’d prefer to leave your details, please use the form below and we’ll get in touch as soon as we can.