Our HM range of Nanoindenters

-

HM2000

Hardness tester with programmable XYZ stage for automated measurements in the load range of 0.1-2,000 mN.

-

HM2000S

Cost-effective and compact manual hardness tester for measurements in the load range of 0.1-2,000 mN.

-

HM500

Hardness tester with programmable XYZ stage for automated measurements in the load range of 0.1-500 mN.

Fischer hardness testers are professional measurement instruments for the analysis of mechanical and elastic properties of materials by means of nanoindentation. Their very rigid and stable construction (marble block base – HM2000 and HM500) reduces the influence of vibrations and fluctuations in temperature. Moreover, their high resolution (XY: +/-0.5μm) XYZ stage (HM2000 and HM500) makes them ideal for routine testing. These instruments are extremely suitable for research and industrial applications.

The measuring head HT2000 of our hardness testers contains a Vickers indenter, the test load generating unit, and the position measurement unit for determining the indentation depth. There’s also always an option to upgrade to Berkovich and Knoop indenters, as well as hard metal spheres and special shapes are available on request. The controlled touchdown of the measuring head leads to a very small machine compliance, allowing much more accurate test results.

The powerful high-resolution microscope on our HM2000 and HM500 hardness testers allows you to focus in on exceedingly small areas. The standard lens comes with x4, x20 and x40 with a video-picture in the software of the area 1,600μm x 1,200μm, 320μm x 240μm and 160μm x 120μm, respectively.

Features and benefits of our HM hardness testers

- Various complex geometry samples can be tested in specific regions thanks to the top down measurement.

- Big samples can be allocated thanks to the spacious measurement table with the usable sample placement area of 180mm x 150mm.

- Measurement and computation of material parameters according to DIN EN ISO 14577-1 and ASTM E 2546Measurement of material parameters according to DIN EN ISO 14577-1 and ASTM E 2546

- Allows the measurement of coatings as thick as 500μm.

- Doesn’t require any sample preparation and outputs precise results with average test times of 60 seconds.

- Programmable XY-Stage and Z-Axis can be automated to measure in predefined positions what allows seamless routine measurements, repetitive and accurate results.

- WinFTM software for seamless measurements, data collection and processing comes pre-installed on PC or laptop.

- Instant results, automated data storage and reporting allows a high throughput of samples.

What are Hardness Testing machines used for?

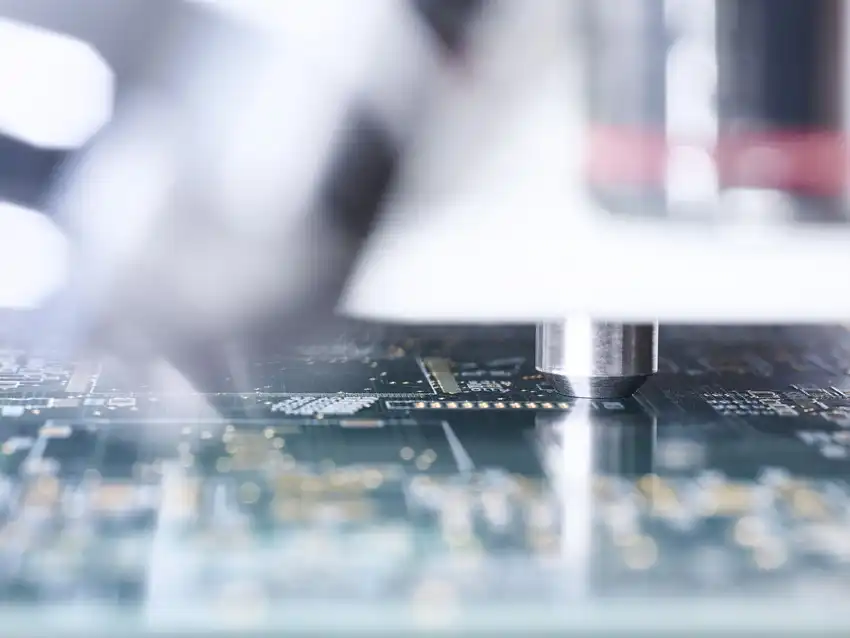

- Measurement of Carbon Fiber Reinforced Plastic (CFRP)Simplifying quality control on PCBs with automatic pattern recognitionD

- Quality control of LCD spacers

- Mechanical characteristics of conformal coatings

- Nanoindentation on wear-resistant DLC coatings applied to engine components

- Mechanical characteristics of anodised coatings

- Determining the mechanical properties of hard coatings used on machining and milling tools

- Hardness measurement of nano coatings on spectacle lenses

Contact us now for more information

Whether you know what type of machine you require or have questions surrounding our product range, we are always happy to assist.

Get in touch and we will help you find the Fischer Nanoindenter solution that best suits your needs. Our team has many years of experience and is always happy to answer your questions.

If you’d prefer to leave your details, please use the form below and we’ll get in touch as soon as we can.