High throughput of small or large electroplated components or parts is completely essential for numerous manufacturing businesses in the world. Even a slightest downtime can add significantly increased manufacturing costs that may lead to a less competitive and overpriced final product or reduced margins.

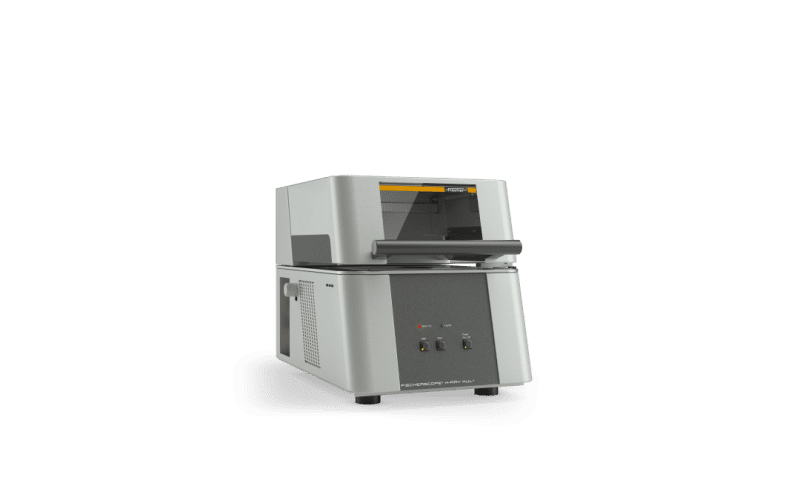

Helmut Fischer GmbH has developed a cost-effective and robust FISCHERSCOPE ® X-RAY XUL ® and XULM ® XRF series for fast plating inspection procedures. This way, the quality of the final product is continuously checked and sustained. Meanwhile, the end user is fully reassured and satisfied with the agreed plating thickness.

The FISCHERSCOPE ® X-RAY XUL ® and XULM ® XRF series are designed as entry level bench-top XRF machines. They are the best solution for fast determination of coating thickness in electroplating, where a large number of samples must pass through quality control as swiftly as possible.

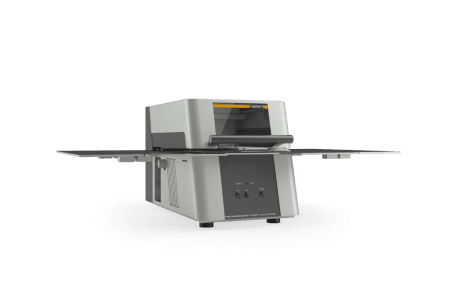

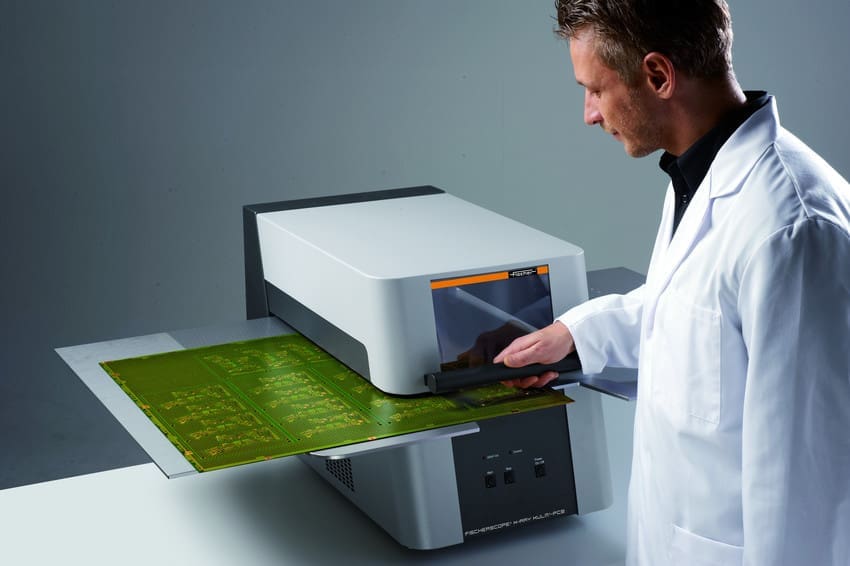

Despite their compact size, these instrument feature a high volume measurement chamber (max. sample height – 174mm or 6.8in) so even bulky objects can be measured. At the same time, an opening in the housing (c-slot) allows for measurements on wide flat samples such as printed circuit boards (PCB).

In order to allow quick and easy sample positioning, the X-ray source and the detector are positioned in the instruments’ lower chamber. Hence, the measuring direction is from underneath the sample that is supported by a transparent window.

This feature offers easy sample positioning and fast routine measurements. An optionally available manual XY-stage on XUL 220 and XULM240 facilitates the exact alignment of small parts. Meanwhile, an intuitive control panel on the front of the unit further simplifies a measurement procedure.

FISCHERSCOPE ® X-RAY XUL ® and XULM ® XRF series are equipped with proportional counter tube detectors that allow the measurement of a wide range of elements – Chlorine (17) to Uranium (92). However, the main difference between all models is the combination of filters and measurement spots sizes. The robust and entry level XUL® 210 features a single Ø 0.3mm aperture with one filter.

Meanwhile, XUL® 220 has the same setup as XUL® 210 but additionally has a manual XY stage. XULM® 240 has 4 interchangeable measurement spot sizes [Ø 0.1 mm (3.9 mils); Ø 0.2 mm (7.9 mils); 0.05 x 0,05 mm (2 x 2 mils); 0.2 x 0.03 mm (7.9 x 1.2 mils] and 3 filter modes (no filter, Aluminium and Nickel), making it ideal for measurement on small components (e.g. connectors).

FISCHERSCOPE® X-RAY XUL® FEATURES AND BENEFITS

- X-ray tube with W-anode and glass window (XUL® 210 & 220) or micro-focus X-ray tube with W-anode and beryllium window (XULM® 240)

- 4 interchangeable aperture sizes (down to 0.05mm x 0.05mm) to allow to focus and measure in localised spots (XULM® 240)

- Extremely safe. Thick metal shielding fully protects operators and visitors from hazardous X-ray energy

- Doesn’t require any sample preparation and outputs precise results with typical test times of 10 seconds

- Spacious chamber accommodates large, small and wide flat samples

- Various sized samples can be tested in specific regions thanks to the bottom up measurement

- Large samples can be allocated thanks to the spacious chamber with the usable sample placement area of 310x320x174mm

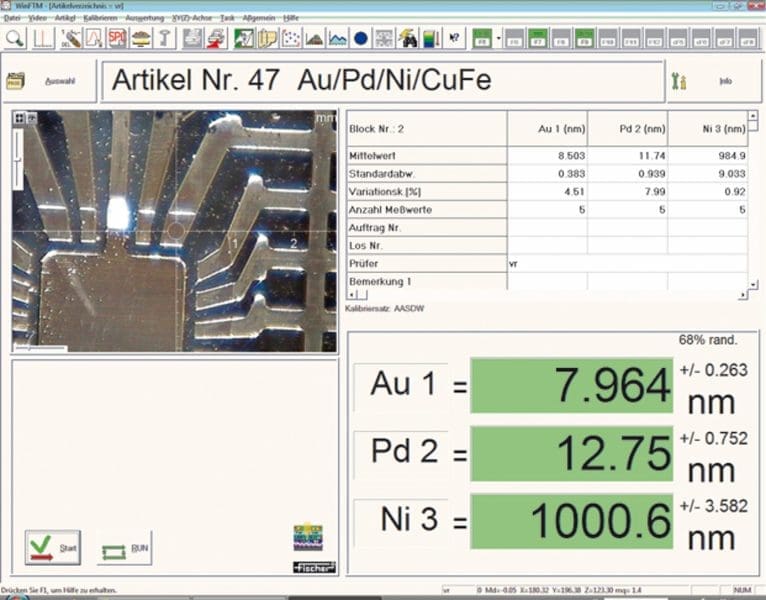

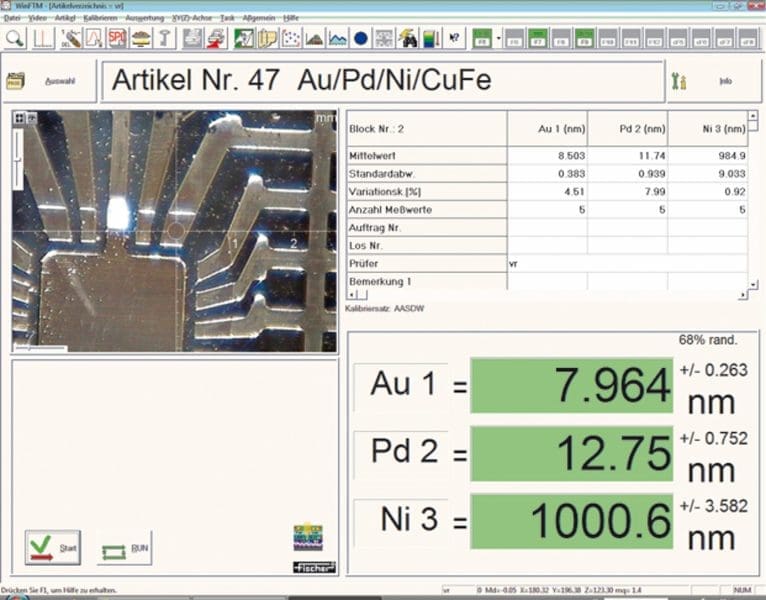

- WinFTM software comes pre-installed on a PC or laptop for seamless measurements, data collection and processing

- Instant results, automated data storage and labelling allows a high throughput of samples

Materials Identification

Material analysis is achieved using the XRF method and Fischer’s range of instruments have the capability to identify unknown materials. The ‘Material ID’ function is easily configured to identify an unknown sample by comparing the spectrum with a library of stored reference spectra. The library can be edited and customised by the user to incorporate known materials and utilised for ‘goods in’ testing for example.

Plating Solution Testing

The quality of metallic coatings depends heavily on the formulation of the plating bath solution, which consequently needs to be monitored. Compared with other methods like titration, XRF analysis of such solutions is straightforward.

Sample preparation and XRF testing is quick, and clean as opposed to other analytical methods where gases (Ar) or purified water are used. These can be messy, time consuming and the results subjective.

WinFTM Software

The supplied Fischer WinFTM software has full SPC (Statistical Process Control) functionality for optimisation of measurements and control of quality throughout the manufacturing process.

Reporting

All Fischer X-ray instruments are supplied with a fully-featured software package that includes a report editor module.

Optimise your workflow, save time and resources, and professionally present the measurement data to your customers. Simply create a template and report your test results directly from the instrument.

Incorporate tables, charts, pictures, spectra, and statistical data into a professional document with your company logo. With one click of a button, the report can be printed as a ‘certificate of testing’ to accompany the goods. The final results can also be exported to Excel, CSV, and PDF formats.

Training

You will have received an onsite installation training session when the machine is commissioned. This is designed to get you up and running.

Many customers, however, request additional training after a few weeks or months – because usually, questions relating specifically to their measurement application and production activities arise sometime after they start using the X-ray.

Also, with time, the original operators may leave the company, and a proper handover of knowledge relating to the instrument does not occur – so invariably key information gets forgotten or its importance diluted.

Make sure you keep trained, informed, and knowledgeable about your X-ray and of its capabilities.

Technical support, advice, and information are free: call our applications support line and speak directly with a Fischer technician.

Contact us now for more information

Whether you know what type of machine you require or have questions surrounding our product range, we are always happy to assist.

Get in touch and we will help you find the XRF machine that best suits your needs. Our team has many years of experience and is always happy to answer your questions.

If you’d prefer to leave your details, please use the form below and we’ll get in touch as soon as we can.