Ensuring Compliance with RoHS by Using the X-Ray Fluorescence (XRF) Method

It is critical for manufacturers and distributors of many products to be able to detect harmful substances. Various regulations, such as RoHS (Restriction of Hazardous Substances), DIN EN 71 (Safety of Toys Standard) and CPSIA (Consumer Product Safety Improvement Act), specify maximum permissible values, particularly for heavy metals.

For example, the RoHS limits concentrations of lead (Pb), mercury (Hg), hexavalent chromium (Cr VI) and bromine compounds (PBB, PBDE) to 1000 ppm, while the limit for Cadmium (Cd) is just 100 ppm.

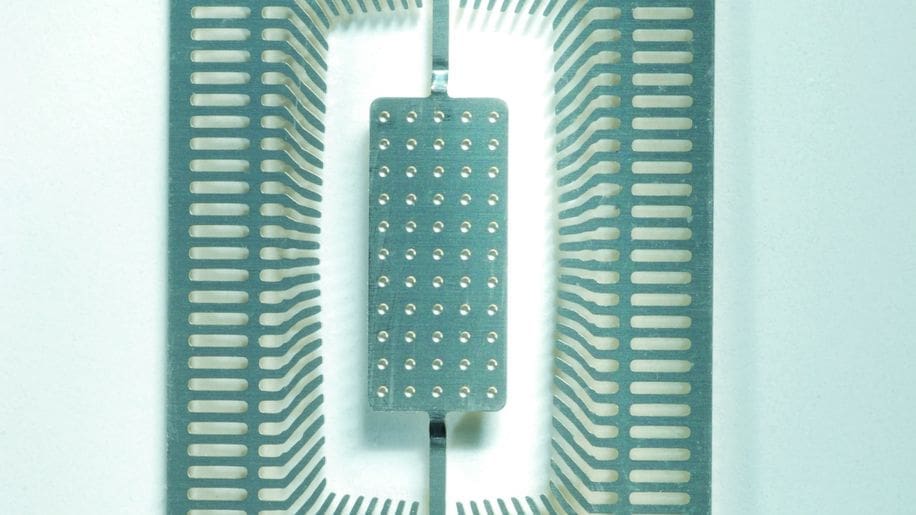

X-ray fluorescence instruments with silicon drift detectors, such as the FISCHERSCOPE® X-RAY XDV®-SDD, are exceptionally well suited for easy, non-destructive determination of these harmful substances in a wide range of products.

| PLASTICS | ALUMINUM/ CERAMICS | BRASS | STEEL | SOLDER | |

|---|---|---|---|---|---|

| 2 ppm | 6 ppm | 50 ppm | 30 ppm | 60 ppm | |

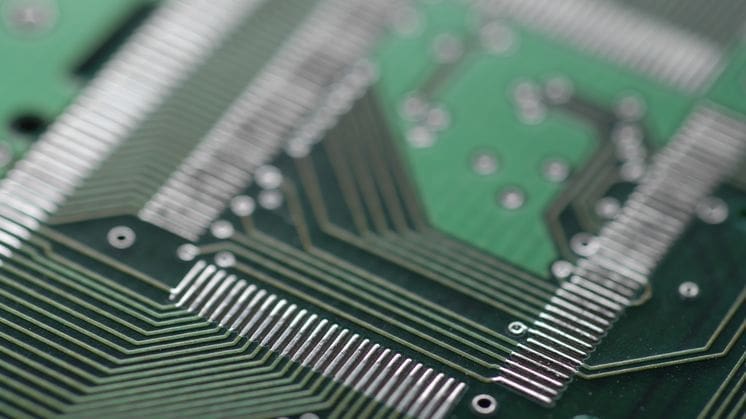

| Housing cable sheathing, PCBs | Housing, SMD components | Plug contacts | Housing | Solder points, bailed samples | |

| Permissible limits: | RoHS: | 1000ppm | |||

| DIN EN 71: | 90ppm | ||||

| CPSIA: | 100ppm |

Detection limits of Pb in various materials/components measured using the FISCHERSCOPE® X-RAY XDV®-SDD compared to the limit values of various regulations.

WinFTM®, FISCHER’s powerful analysis software, includes a mode specifically developed for RoHS analysis which provides for automatic evaluation of adherence to limit values.

Thus, compliance with legal requirements can be verified quickly, with typical measuring times of 60-300 seconds.

The FISCHERSCOPE® X-RAY XDV®-SDD.

Table 1 illustrates the detection limits for Pb in various materials using the X-ray fluorescence method. While direct measurement is possible for Pb, for Cr and Br only total concentrations – not the exact concentrations of the harmful compounds – can be determined. Compliance is established when the total concentration is below the limit values, otherwise additional analysis methods must be employed. The required detection limits can also be met for other heavy metals as well, such as Cd, Hg, As, and Ba.

Your local contact person for FISCHER products will be happy to assist you in selecting a suitable X-ray fluorescence instrument for measuring very small concentrations of harmful substances – FISCHERSCOPE® X-RAY XDV®-SDD, XAN® 150 with SDD detector, or XDAL® with PIN detector.