Our universal XRF range

-

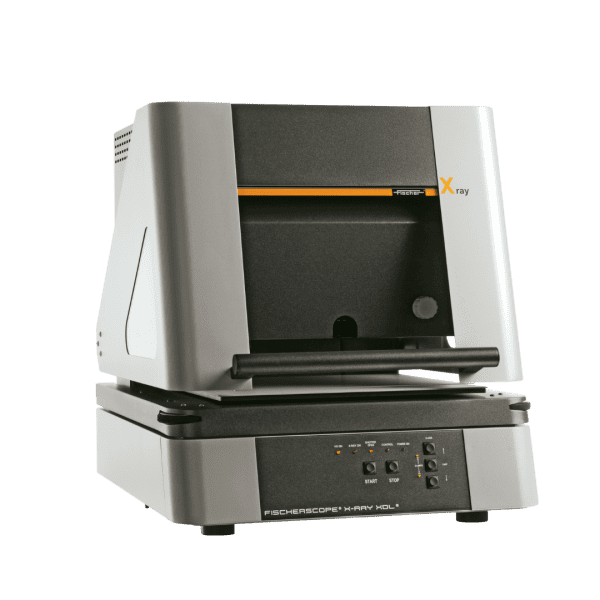

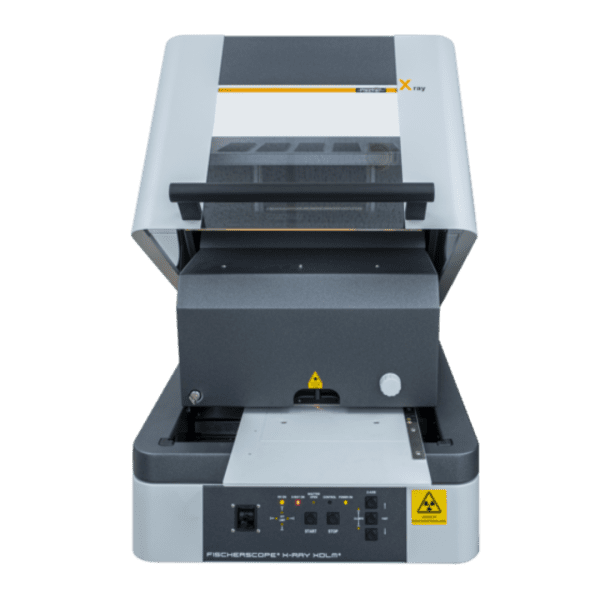

XDL® 230/240

Manual and programmable XYZ stage with a fixed 0.3mm diameter X-ray aperture. Cl (17) to U (92)

-

XDLM® 237

Programmable XYZ stage with various X-ray aperture sizes (in mm: 0.1, 0.2, 0.05×0.05, 0.2×0.03). Cl (17) to U (92)

-

XDAL® 237

Same as XDLM model but with Silicon Drift Detector. Significantly increased detection limits. Al (13) to U(92)

Features and benefits of our universal XRF machines

- Precise coating thickness evaluation of Gold, Palladium and Nickel layers on Copper in PCB applications (XDAL).Simplifying quality control on PCBs with automatic pattern recognitionD

- Simplifying incoming good inspection and quality assurance on PCBs with automatic pattern recognition.

- Directly measurable concentrations of phosphorous content in Electroless Nickel applications (XDAL)

- Measurement of Cr/Ni/Cu coatings on plastic substrates

- Analysis of harmful substances textiles for Oeko-Tex certification

- Trace element analysis (mainly led and cadmium) in materials for fashion jewellery and accessories

- Identification of undesirable substances (e.g. heavy metals) in electronics, packaging and consumer goods to RoHS, WEEE, CPSIA and other guidelines.

What are universal XRF machines used for?

- Various complex geometry samples can be tested in specific regions thanks to the top down measurement.

- Big samples can be allocated thanks to the spacious chamber with the usable sample placement area of 370x320x40mm.

- Extremely safe. Thick metal shielding fully protects operators and visitors from hazardous X-ray energy.

- Highly small XDLM and XDAL 0.1mm aperture size allows to focus and measure in exceedingly small spots.

- Doesn’t require any sample preparation and outputs precise results with average test times of 5 seconds.

- Programmable XY-Stage and Z-Axis can be automated to measure in predefined positions what allows seamless routine measurements, repetitive and accurate results.

- XDAL precise recognition of low intensity elements accommodates for repetitive and accurate:

– coating thickness measurements in nanometers range (e.g. as low as 2nm of Gold).

– small concentrations in the trace analysis to RoHS &WEEE - WinFTM software for seamless measurements, data collection and processing comes pre-installed on PC or laptop.

- Instant results, automated data storage and labelling allows a high throughput of samples.

XDL models are universally applicable XRF machines. They are particularly well suited for non-destructive measurements of thin coatings on irregularly shaped and flat parts, as well as for the liquid solution analysis. The flexibility of measurements is achieved thanks to the large chamber that accommodates top-down measurement method with a large enough gap in the housing to measure on extremely wide flat samples (e.g. printed circuit boards or long electroplated sheets). Nevertheless, the flexibility of measurement distance allows to perform measurements far away from a sample.

Designed with an easily programmable XY-Stage and Z-Axis (XDL240, XDLM237 and XDAL237), the machines can be automated for measurements of extremely thin coatings and material analysis even by untrained operators. Outstanding accuracy and long-term stability are characteristics of all Fischer XRF systems.

Powerful Silicon Drift Detector in XDAL can identify a wide range of materials Al(13) to U(92) within just 5 seconds. Meanwhile, more basic Proportional Counter Tube detector on XDL and XDLM models offer a cheaper alternative while still covering a wide range of elements Cl (17) to U(92). At the same time, micro-focus X-ray tube with tungsten target and beryllium window ensures long-lasting service for many years. The necessity of re-calibration is dramatically reduced, saving time and effort as all instruments are calibrated to your specific applications before the delivery.

Contact us now for more information

Whether you know what type of machine you require or have questions surrounding our product range, we are always happy to assist.

Get in touch and we will help you find the XRF machine that best suits your needs. Our team has many years of experience and is always happy to answer your questions.

If you’d prefer to leave your details, please use the form below and we’ll get in touch as soon as we can.